Intake Station

Automatic raw material receiving control system – safe, accurate and with real-time data

Intake Station

Automated Raw Material Intake System – Safe, Accurate, and Real-Time Data

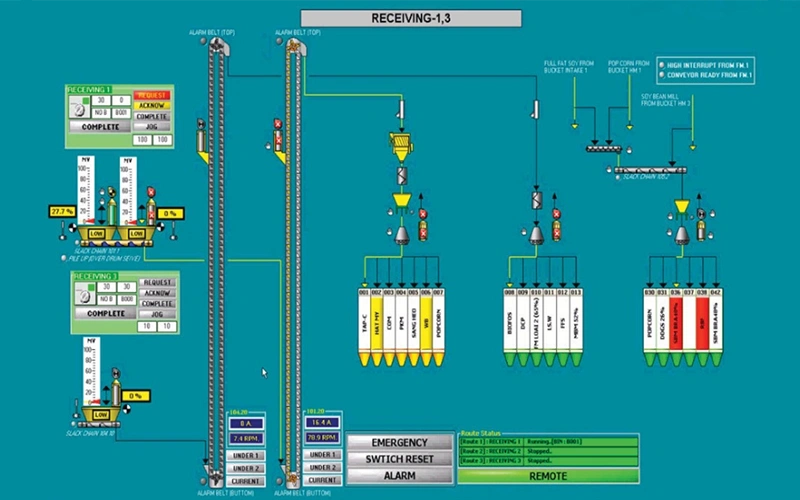

The Intake Station is an advanced solution for managing raw material intake at single or multiple points. It ensures that each type of material is delivered to the correct silo with precision and safety. With real-time stock monitoring and movement tracking, this system minimizes the risk of cross-contamination or incorrect tipping and enhances overall inventory management efficiency.

Features :

● Real-time stock tracking with full traceability

● Direct integration with weighbridge systems for accurate measurement

● Barcode-initiated tipping process for speed and error reduction

● Automated conveyor control (Start / Stop / Hold functions)

● Fully compatible with Route Control and In-flight Weighing Systems

● Information and message display system at each intake point

Benefits :

● Prevents silo misfilling and cross-contamination of raw materials

● Enables accurate control of bulk material intake

● Provides up-to-date and reliable inventory data

● Optimizes silo space and raw material utilization

Ensures continuous raw material supply for smooth production operations