Smart Premix

“Intelligent system for accurate and efficient preparation of adjuvants”

Smart Premix

“Smart Premix System for Accurate and Efficient Supplement Preparation”

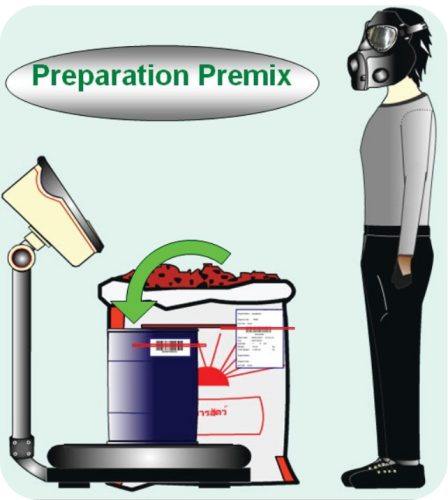

Smart Premix is a comprehensive system designed to manage and control the manual preparation and dosing of feed supplements (premix) with high accuracy, traceability, and integration with the Smart Batching system. It was developed to eliminate errors, reduce production losses, and enhance reliability across your entire feed production process.

This system focuses on:

Reducing risk of human error

Providing complete traceability across all operations

Ensuring precise and reliable data

Improving overall workflow efficiency

Smart Premix Overview

With years of experience in feed mill operations, we understand that premix preparation is a sensitive and error-prone process. That’s why we created Smart Premix a solution tailored for manual weighing, supplement mixing control, and specialized stock management.

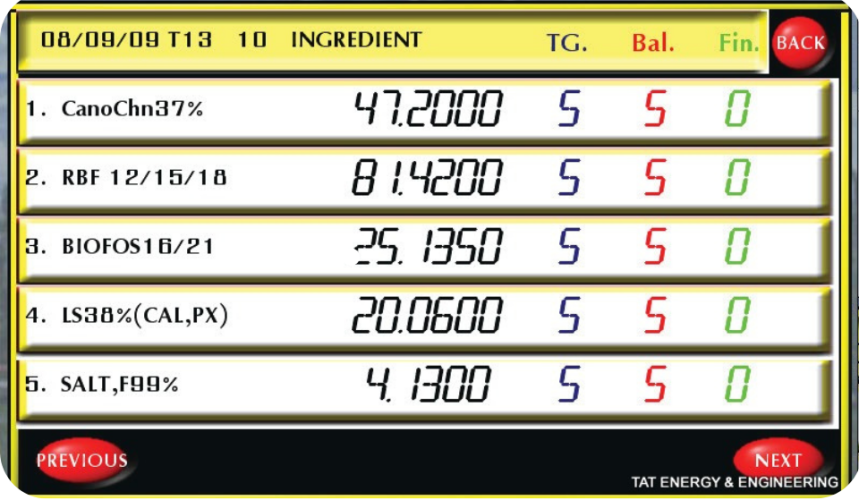

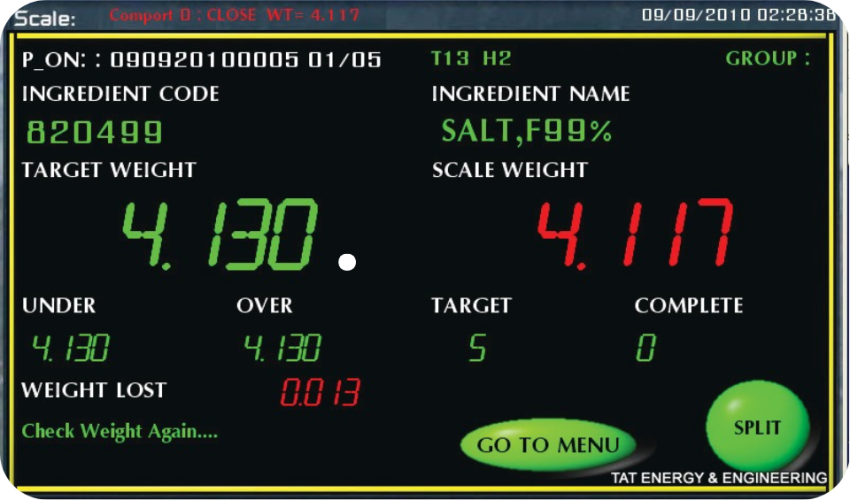

Using Touch Panel Computers connected to precision scales at multiple station points, Smart Premix operates in a Client-Server network, allowing for multiple weighing stations to run simultaneously. This supports flexible management of weighing tasks and boosts productivity.

Smart Premix is fully integrated with Smart Batching, ensuring that each supplement batch is weighed, mixed, and dosed exactly according to formula 100% accurately and traceable from start to finish.

Features :

Seamless integration with weighing scales and label printers

Controlled premix weighing process

Controlled premix dosing based on Smart Batching formulas

Slide gate control for secure Handadd operations

Barcode scanning system to confirm identity before and after weighing

Inventory management system specifically for feed supplements

Expiry date monitoring & control

FIFO (First-In, First-Out) material usage management

Job Assignment system for weighing and mixing planning

Full Reporting & Traceability: including operator name, batch ID, lot number, supplier, expiry date, and weighing station

ERP connectivity for seamless data exchange between systems