Smart Batching

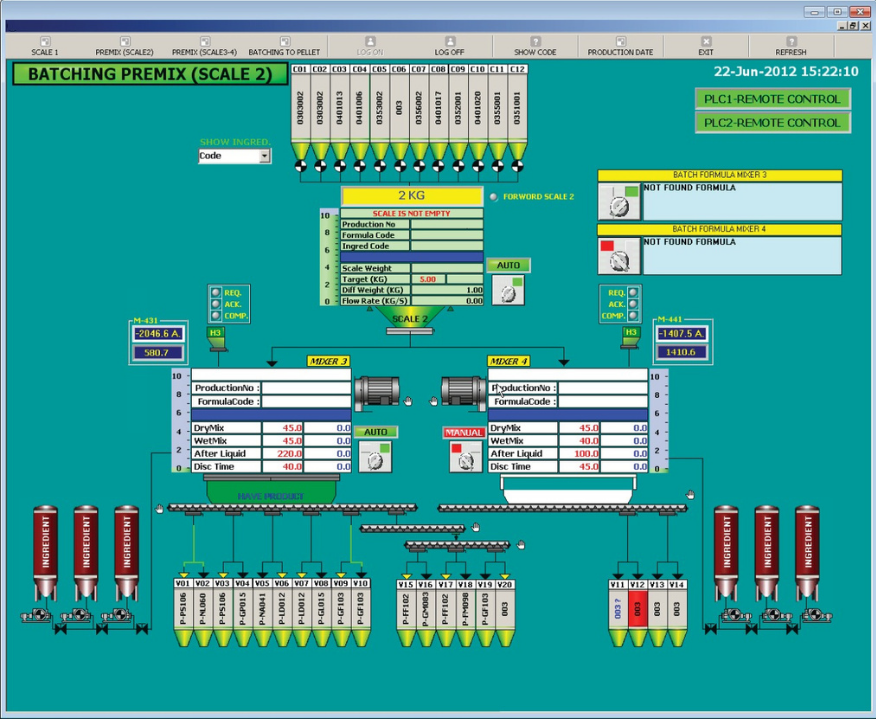

“Intelligent food weighing and mixing control system”

Smart Batching

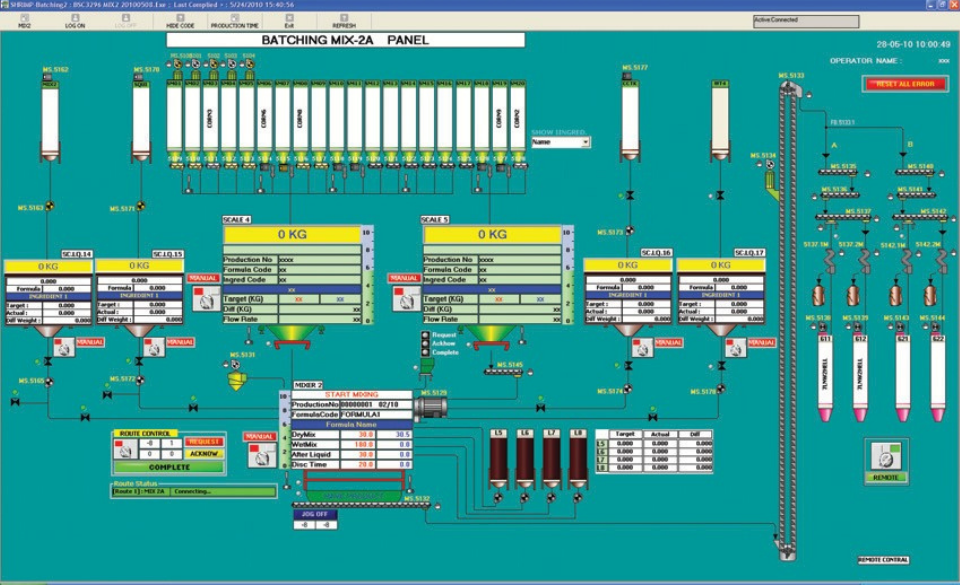

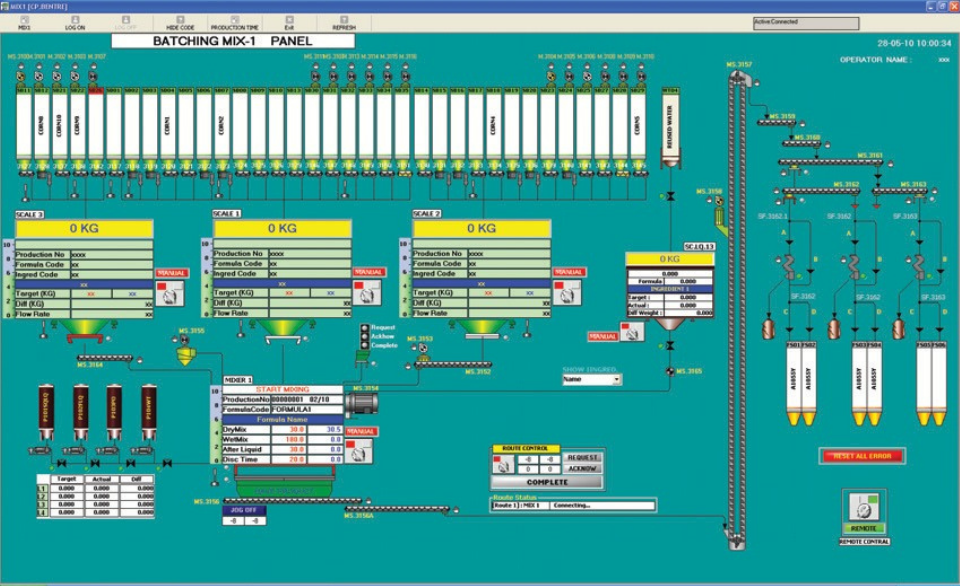

“Intelligent Feed Mixing and Weighing Control System”

Smart Batching is the heart of modern feed production systems—designed for precision, speed, consistency, and end-to-end process control. Developed by TAT, this intelligent solution ensures efficient operations, clear production data visibility, real-time alerts for abnormalities, and contamination prevention. It even includes container verification and event logging for traceability and future analysis through the Smart Batching Report system.

Core System Components

1. Weighing

Interfaces seamlessly with high-precision, high-speed weight indicators

Supports Micro Scales and simultaneous weighing of up to 3 bins

Automatically calculates freefall for accurate dosing

Compatible with variable speed control for precise material delivery

2. Handadd

Supports manual ingredient addition with or without weight indicators

Ensures proper verification before adding to the mixer

3. Mixing

Supports both dry and wet mixing processes

Customizable mixing times for each formula

4. Liquid Handling

Compatible with Scale-based, Loss-in-Weight, and Flow Meter (Pulse) liquid dosing systems

Interfaces with third-party control systems seamlessly

5. Formula Interface

Allows recipe imports via Text File, XML, Email, etc.

Minimizes manual data entry errors and speeds up recipe setup

6. Contamination Control

Built-in checks to prevent raw material and product contamination

Supports automatic line flushing (Auto Cleaning) to maintain hygiene

7. Job Assignment

Enables batch planning in advance

Users can define recipe production sequences, number of batches, and product routing to destination bins

8. Automatic Routing

Automatically configures machinery routing paths

Verifies destination bins and routes for accuracy

Includes contamination prevention protocols and clean-time automation to avoid leftover residue in the production line

Smart Batching Report

A comprehensive reporting tool that works alongside the production system to log essential data, monitor contamination settings, and generate insightful production reports.

Features:

Ingredient Configuration

Pending Formula Configuration

Active Formula Configuration

Contamination Configuration

Daily Batch Reports

Summary Reports (by Ingredient / Formula)

Parameter Reports

Alarm Logger

Job Reports

Data Export Capability

Smart Batching is your intelligent solution for precise, safe, and efficient production management.

Whether you’re looking to improve traceability, optimize batching, or eliminate manual errors—Smart Batching brings your operations one step closer to world-class manufacturing standards.